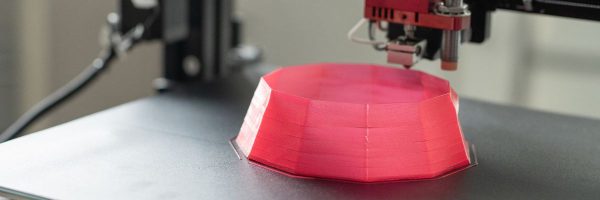

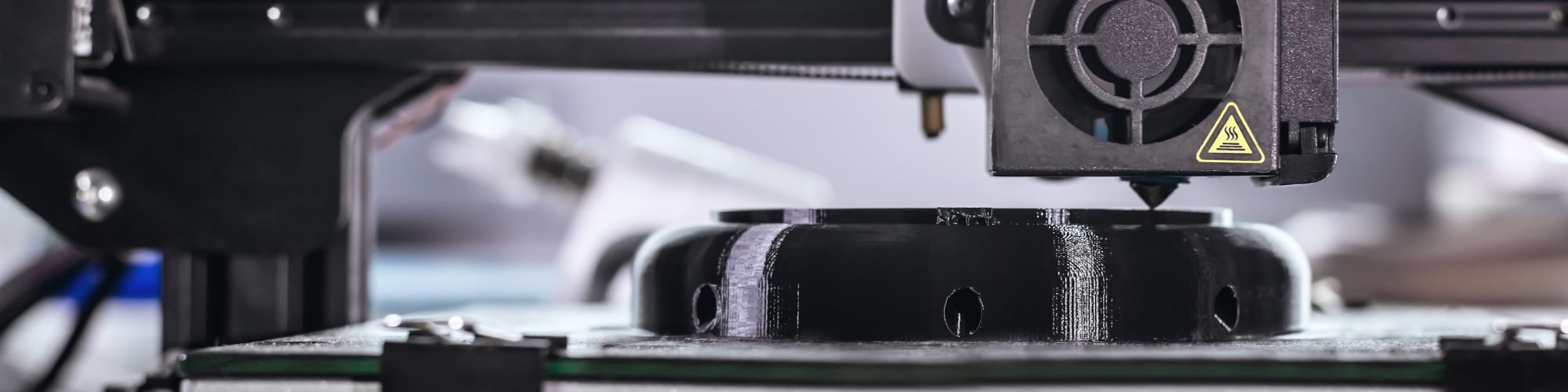

Miniature motors and gearboxes bring accuracy, consistency, and efficiency to robotic and 3D printing applications.

From articulated robotic joints to high‑resolution additive manufacturing systems, Rotalink’s motion technology provides the fine control, torque, and reliability needed for precision automation in compact spaces.

Rotalink’s miniature motion systems deliver dependable performance across advanced robotic platforms and precision additive manufacturing. Our gearmotors and assemblies enable: