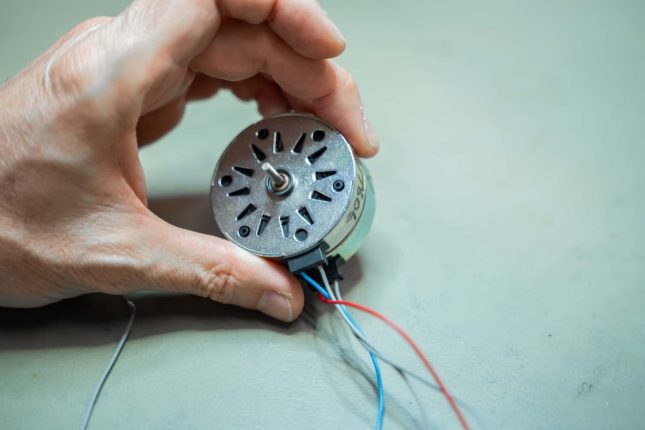

Miniature motors and gearboxes are critical to the smooth, reliable operation of cash handling systems and Automated Teller Machines (ATMs).

Their compact size, torque output, and durability enable precise mechanical control for transporting, counting, stacking, and dispensing currency in secure and space‑limited environments.

Rotalink’s miniature motors and gearboxes deliver precision, torque, and reliability in every stage of cash handling — from validation and storage to dispensing. They provide: