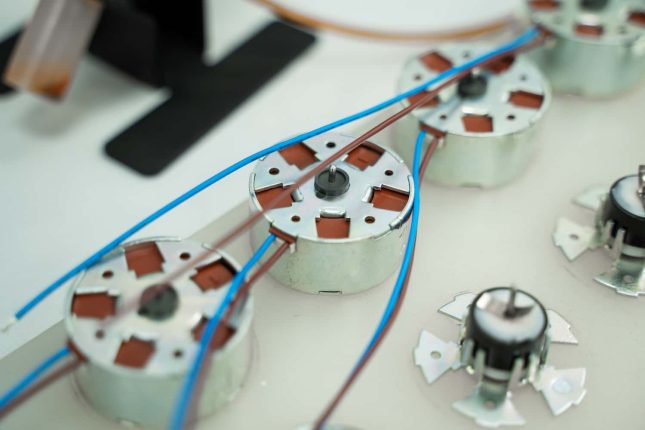

Miniature motors and gearboxes play a vital role in dosing and metering systems, providing the torque, speed control, and precision required for accurate fluid delivery.

Rotalink’s motion systems ensure repeatable dosing, reliable operation, and consistent flow control across chemical, pharmaceutical, food, and environmental applications.

Rotalink’s miniature motors and gearboxes provide smooth, accurate motion for metering, mixing, and injection systems. Our motion technology offers: