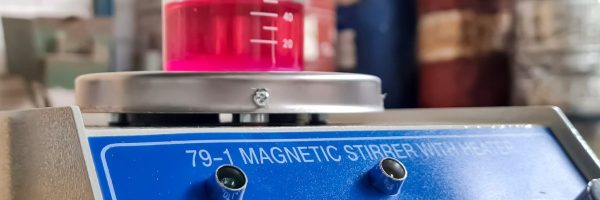

Rotalink’s miniature motors and gearboxes provide precise, durable, and quiet motion control for hotplate stirrers and other laboratory mixing systems.

Our motion solutions ensure consistent, torque-rich performance in compact designs — maintaining reliable operation even under heat, continuous duty, and varying fluid viscosities.

Rotalink’s miniature gear motors combine smooth torque delivery and speed precision for laboratory mixing applications. Our motion systems offer: