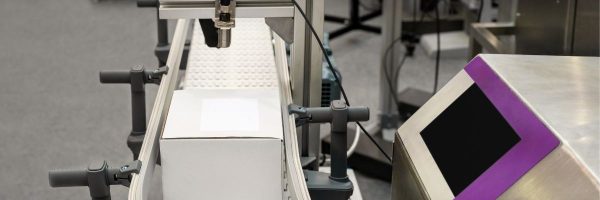

Miniature motors and gearboxes are essential in labelling and dispensing systems, delivering accuracy, repeatability, and speed in compact designs.

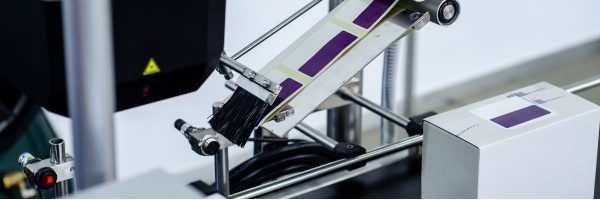

Rotalink’s motion solutions power label feeds, applicator arms, and dispensing mechanisms used in packaging, production, and laboratory environments — ensuring smooth, reliable operation across high‑duty cycles.

Rotalink’s miniature motors and gearboxes provide the controlled movement required for precision labelling and dosing systems. They offer: