Miniature motors and gearboxes play a vital role in automating and controlling fluid and mechanical systems within modern milking parlours.

Rotalink’s motion systems provide the accuracy, torque, and reliability required for efficient milking, fluid transfer, feeding, and cleaning processes — supporting improved productivity, hygiene, and animal welfare.

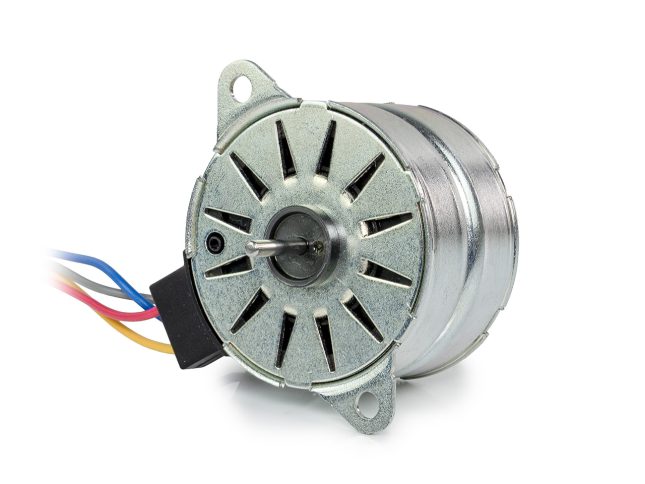

Rotalink’s miniature motors and gearboxes automate and control key processes in milking parlours, ensuring consistent performance and reduced manual effort.

Our motion systems provide:

Motor gearboxes are used throughout fluid control systems to reduce speed and increase torque, delivering precise control over flow and pressure. Common applications include:

In milking parlours, motor gearboxes automate mechanical and fluid-handling systems, enhancing efficiency, hygiene, and consistency across daily operations: