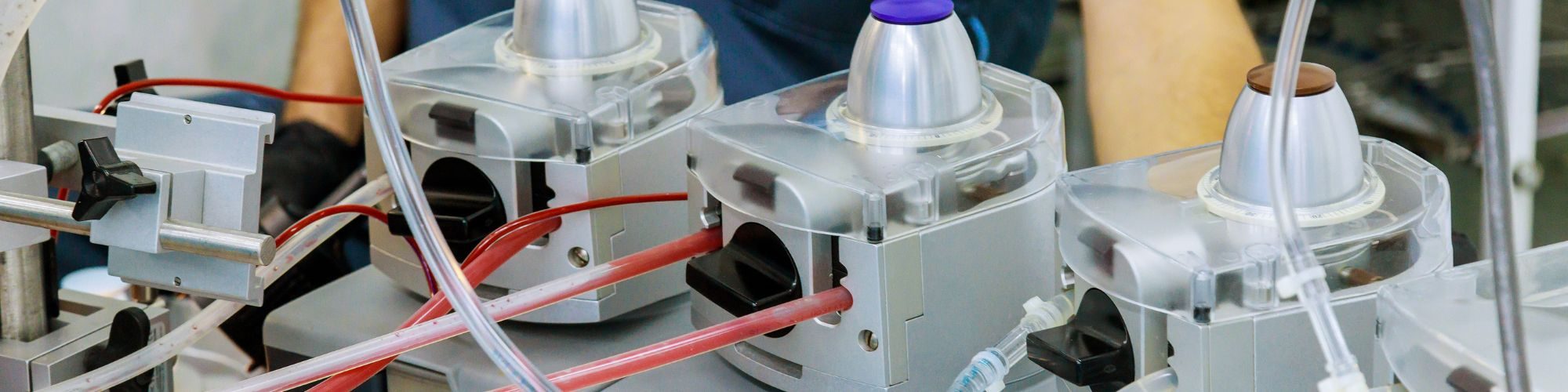

Miniature motors and gearboxes play a vital role in the operation of peristaltic pumps used across medical, laboratory, industrial, and environmental applications.

By compressing flexible tubing to move fluids, peristaltic pumps provide contamination-free transfer with precise flow control.

Rotalink’s compact motion systems enable these pumps to deliver consistent performance, smooth operation, and reliability in even the smallest devices.

Miniature motors and gearboxes deliver the torque, precision, and reliability needed for consistent pumping.

Their compact size allows for integration into portable and low-power systems while maintaining high levels of performance.

Rotalink motion technology enables: