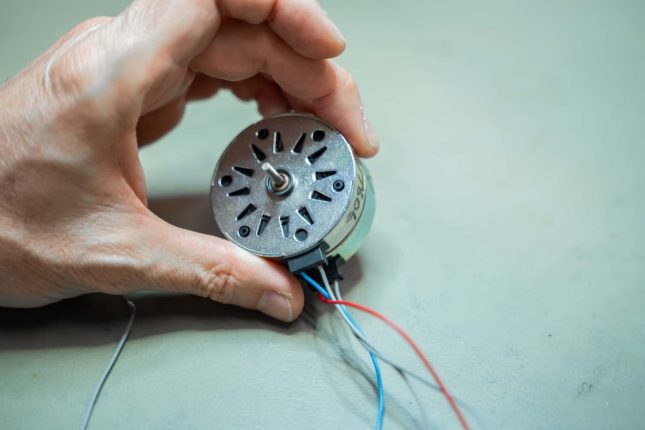

Miniature motors and gearboxes provide precise, reliable, and efficient motion for pump systems across industrial, commercial, and environmental applications.

Rotalink’s motion technology delivers controlled torque and speed for centrifugal, metering, vacuum, and hydraulic pumps — ensuring consistent performance, low noise, and long service life.

Rotalink’s miniature motors and gearboxes enhance pump systems by delivering the precision, torque, and control needed for smooth, reliable operation.

Our motion systems provide: