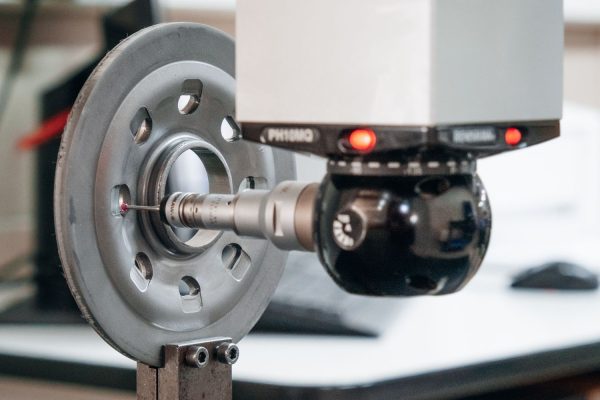

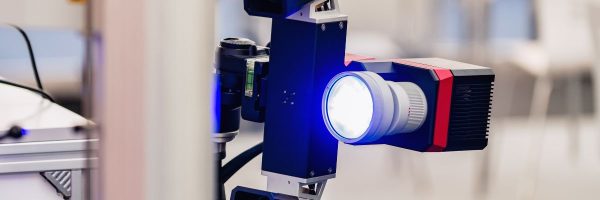

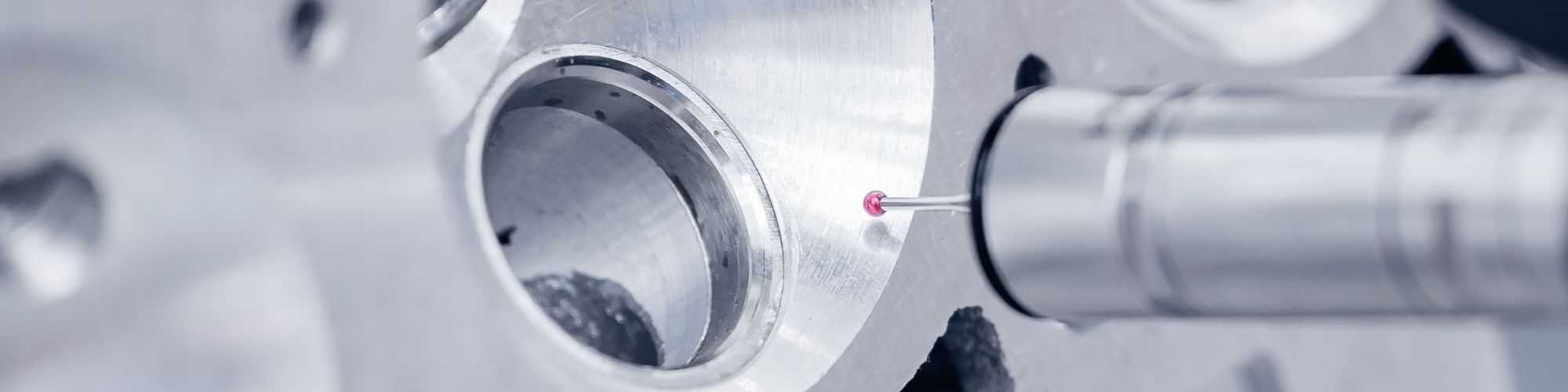

Test automation relies on repeatable, precise, and efficient motion.

From robotic test fixtures to endurance rigs and calibration systems, Rotalink’s miniature motors and gearboxes provide the controlled movement, torque, and accuracy needed to simulate real‑world conditions and ensure product reliability.

Miniature motors and gearboxes enable precise, programmable movement for test automation, calibration, and simulation. Rotalink’s motion systems deliver: