Discover how Rotalink’s miniature gearmotors can be used in 3D printing. From powering precise movements to ensuring efficient operation, our gearmotors play a pivotal role in enabling the creation of intricate and complex structures with unparalleled accuracy and reliability.

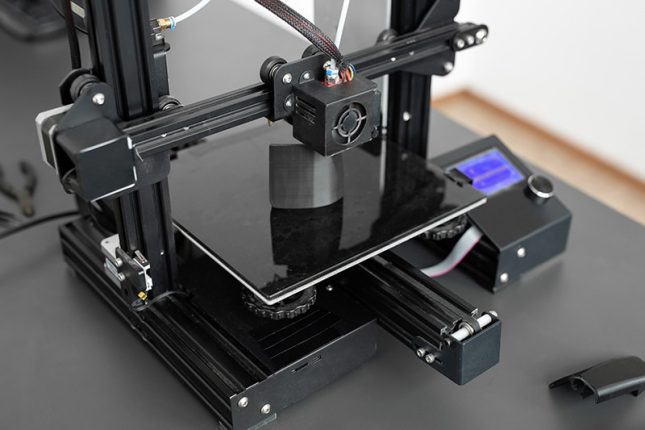

In manufacturing, miniature gearmotors drive the intricate movements and precise operations of 3D printing technology. Let’s look at how the miniature gearmotors we produce here at Rotalink can be used in 3D Printers.

Miniature gearmotors are used for motion control in 3D printers, allowing the precise movement of print heads, build platforms, and other essential components along multiple axes.

Leveraging the accuracy of stepper motors, these gearmotors facilitate meticulous layer-by-layer printing, ensuring the seamless execution of intricate designs.

Efficient filament handling is vital in 3D printers, and miniature gearmotors play a vital role in ensuring smooth operation.

From spool holders to feeder mechanisms, gearmotors regulate the movement of filament, guaranteeing consistent and reliable material flow throughout the printing process.

Maintaining optimal temperatures is key to successful 3D printing and ensuring accurate models can be produced.

Miniature gearmotors contribute to this by powering cooling systems. By regulating temperatures around the print head or build platform, our motors can ensure ideal printing conditions, resulting in superior print quality and reliability.

Achieving precise bed levelling is essential for flawless prints, and miniature gearmotors make it possible through automated bed levelling systems. These motors adjust the height and alignment of the print bed with utmost precision, facilitating proper adhesion and uniform layer deposition for impeccable results.

Miniature gearmotors extend their influence beyond core printing functions, powering peripheral devices such as cooling fans, automatic door mechanisms, and auto-bed-changing systems. These auxiliary components further enhance the efficiency and functionality of 3D printing setups, contributing to a seamless printing experience.

At Rotalink, we specialise in the design and manufacture of miniature gearmotors tailored to the unique needs of 3D printing applications. Our gearmotors combine cutting-edge technology with meticulous craftsmanship, ensuring unparalleled performance and reliability.

With a diverse range of options and customisation capabilities, Rotalink gearmotors are the perfect choice for enhancing the precision and efficiency of 3D printing systems.